As the global demand for high-quality vegetable oil continues to rise, the efficiency and oil quality of traditional oil extraction equipment are difficult to meet market demand. This brings many challenges, including low yield, high cost and energy waste.

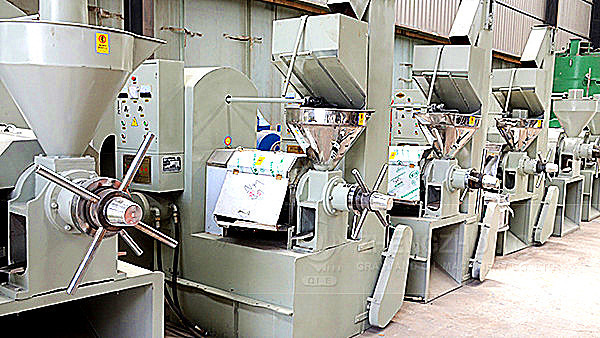

The emergence of high-efficiency oil presses provides effective solutions to the above challenges. According to industry research, modern high-efficiency oil presses adopt advanced automated control systems that can accurately adjust pressing parameters to adapt to the characteristics of different oils, thereby significantly improving oil extraction efficiency and oil quality.

Compared with traditional oil presses, high-efficiency oil presses have made a qualitative leap in energy efficiency and loss. For example:

In addition to significantly improving production efficiency, the high-efficiency oil press also has an environmentally friendly design, reducing waste oil and noise emissions, which meets the needs of modern sustainable development. When enterprises promote the use of high-efficiency oil presses, they can not only improve economic benefits, but also establish a good environmental image and lead the development of the industry.

High-efficiency oil presses are playing an increasingly important role in the modern oil press industry. Through advanced technology and environmentally friendly design, it not only solves many pain points of traditional equipment, but also provides significant competitive advantages for oil production companies. We recommend that companies actively adopt this equipment to achieve higher production efficiency and economic returns.

Learn more about the superior performance of high-efficiency oil presses, contact your suppliers for more information, and help your oil production company stand out from the competition.